Business Update - May 2023

by Bart van de Kooij, on May 15, 2023 7:45:14 PM

In the past months, we have been incredibly busy with getting manufacturing back on track after China’s extensive lockdowns finally ended and closing partnerships with brewing production partners.

In the past months, we have been incredibly busy with getting manufacturing back on track after China’s extensive lockdowns finally ended and closing partnerships with brewing production partners.

Beginning of this year, the Chinese government let go of the strict lockdowns which presented the opportunity for our team (Bart and Steven) to visit the factory after 3 years of not being allowed to enter the country. However, even though here in Europe it already feels like life is back to normal, in China it turned out the impact of COVID wasn’t finished yet. Below is an update on the most relevant items.

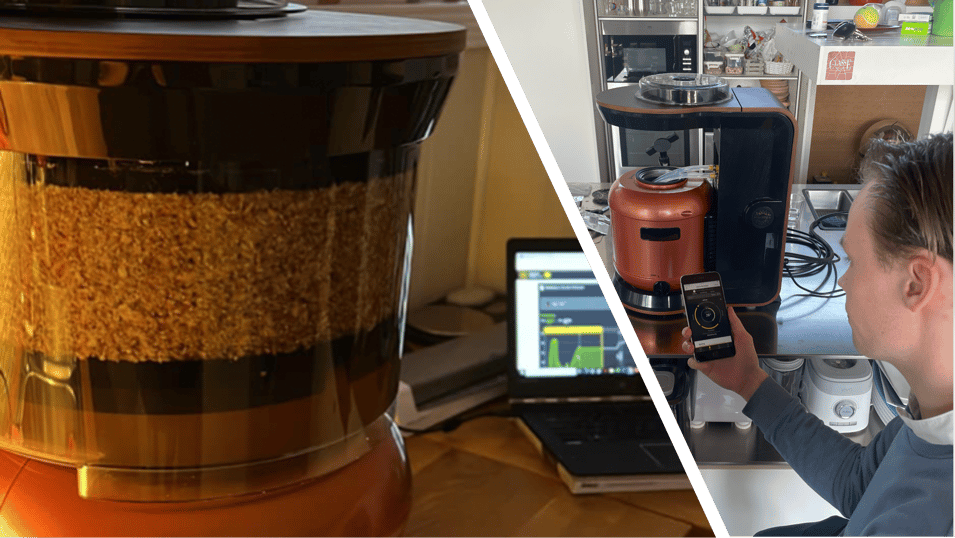

GEN 3 Production Update

In every production process, our main assembly partner is buying components based on lead times and produces components in their facility. In the past, we produced multiple generations from prototypes to GEN 1 and GEN 2, which generated stock of numerous parts at their facility. In October 2022 our main assembly partner checked the status with each vendor who confirmed they are able to deliver parts in time to realise the delivery window from Q2 2023 onwards.

Beginning of December, we communicated that an investment of 1.3 million allowed us to buy components. To ensure we would be able to make the delivery window, even when quarantine rules were still ongoing in China, Our CEO (Bart) decided to visit the procurement team of our main assembly partner / factory (Simatelex) in Hong Kong.

The extra required $600.000 working capital needed was discussed on a component level. In that period the dollar appreciation increased (to even higher levels) and various vendors suffered badly under the strict lockdown regime in China.

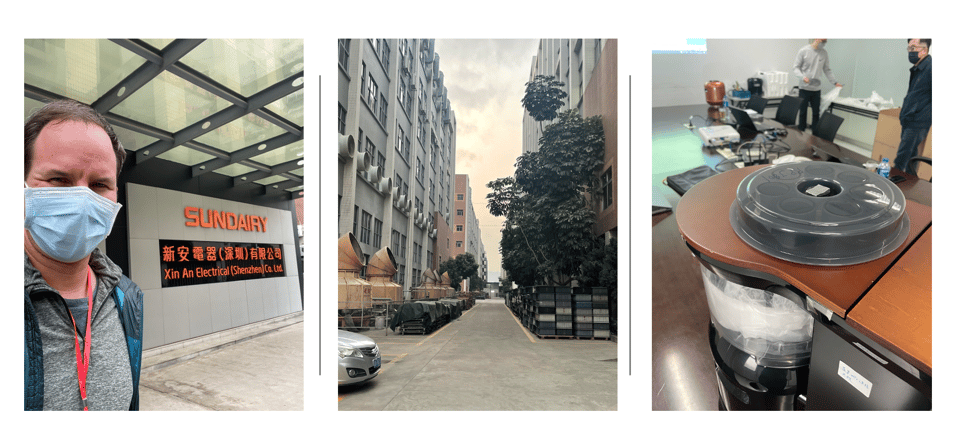

Main Assembly Partner / Factory visit

Beginning of January the government decided to relax the COVID rules and about 400 million people got COVID in China. Despite these high numbers and negative travel advice from my factory, our CEO (Bart) decided to visit the factory in Shenzhen the day after the border opened. The goal was to make sure that the delivery window would be made.

Our CEO (bart) is back at the factory

Our CEO (bart) is back at the factory

Visiting China was not without its challenges. The pandemic had changed the way the country worked and played, and there were various stringent new restrictions and precautions that had to be taken. Nonetheless, the manufacturing team was eager to make new products.

During Bart's visit, we transferred the needed funds in time to our main assembly partner to buy the remaining parts. However, in parallel various things had happened in China and it turned out that several vendors got hurt badly due lack of resources. So we focused a lot of our efforts on finding solutions for this together with our main assembly partner. These proceedings caused a further delay of getting the short lead time items in time.

In March, we had to re-negotiate with several sub-vendors that couldn’t deliver or were severely delayed. Despite working with major suppliers such as NXP, and Qualcomm, they were facing huge backlogs of orders and had limited staff available due to the large number of infections.

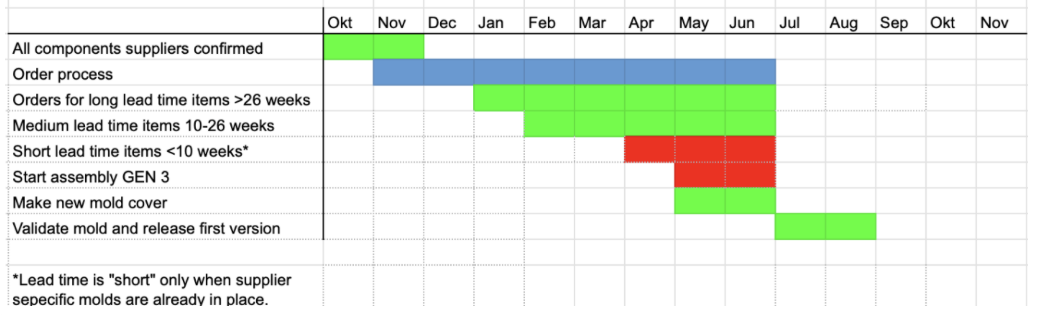

Update Production Planning

Change Wooden back panel

Furthermore, our wooden back panel vendor who would normally be able to deliver within 8 weeks decided to discontinue delivery due to a very large order from a Fortune 500 company that required all their attention.

We considered switching suppliers for the wood, however, realised that it would take time to find a good new supplier (2 months), which required new tooling (2 months), tool release (1 month), and sample build (2 months) which could take easily up to 7 months which will cause a delay in assembly.

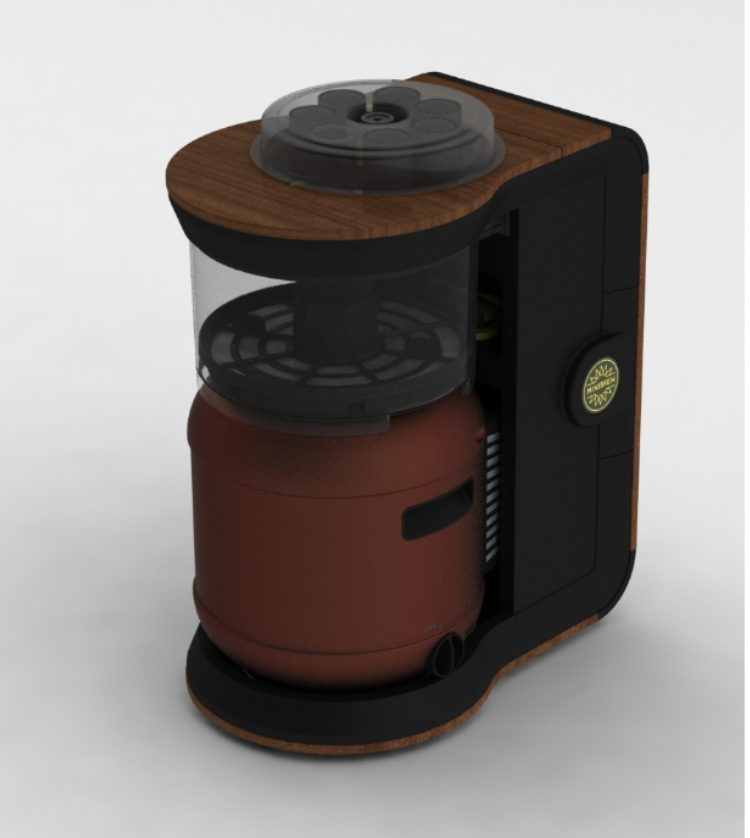

Because of this, we were forced to look at other materials and meet the more stringent demands in time. We made several renders and real prototypes to understand the shape and requirements of the material before pulling the trigger to switch.

Render of MiniBrew with new cover (black angles are not a reflection of the final result)

First prototype based on CAD design. The material is not a reflection of the final result

Mid-April, we decided to go make a robust cover with our main assembly partner. We asked our partner to make a new mold and expect the first tool release test in June 2023. When the tool is confirmed, some samples will be made so we can start production of this component after the summer holiday.

A prototype - the holes in the back don't reflect the final result

Inside look of a prototype panel

The decision to make the cover in our main assembly factory vs buying from a sub-vendor has the advantage that the risk of buying components has been reduced. Furthermore, in-house molding of components is better to control the yield and quality.

Because of this, we need to inform you that the planned shipment will move. If all testing goes perfectly the first time, the plan is that you will get your products after the summer holidays. However, our assembly partner has extensive experience with these kinds of proceedings and tells us that we should put in an additional buffer of around 4-6 weeks after the summer holidays. We know so many of you are looking forward to getting your hands on the new GEN 3 (an improved version) and we want to ask you for a little bit more patience for a couple of months. Each GEN 3 purchaser will been informed by email about this update.

We are still investigating all avenues to see if there are any other ways that we can speed up the timelines. Our team is planning to go at the end of June 2023 to check on the first production release of the GEN 3.

How we aim to prevent future delays

The long-term goal is to order a bigger volume to avoid stock issues and gain a better buying position at sub-vendors. We are talking with investors and retailers to see how we can buy larger volume orders, which would both increase our negotiation position with suppliers and ensure we have sufficient stock and don’t have to pass on any production delays to our customers.

Additional Brew Pack Production Suppliers, more Brew Packs to choose from!

Last year, the brewing industry surfed the choppy waves of hop shortages, a tight labor market, and spiking expenses, which resulted in low stock levels of our Brew Packs. Next to that, we noticed the high shipment cost and custom issues customers face when ordering brew packs. Beginning of this year, we decided to expand our production partners in Switzerland, the UK, and the Netherlands to have more awesome beer recipes available.

We started in Switzerland with Brau & Rauch who’s offering the full range of Brew packs. They are a recognised brew shop, with 5+ years of experience, with their famous tap room, and create their own beers being among the best in the country.

Bart (left) and Rolf visiting B&R to strengthen our partnership

Each brew pack made by Minibrew or the brewery is adjusted to the ingredient availability in Switzerland. Rolf (the left guy) has tested and approved all recipes.

Rolf (left) checking brew pack production at Brau & Rauch

As a result, Swiss customers can order Brew Packs that are made on-demand with the freshest ingredients. You can only order the packs when you live in Switzerland via Brau & Rauch.

If you on't live in Switzerland you can order available Brew packs at Minibrew Shop.

Brewpack portfolio of B&R

In the UK, we started talking with the Maltmiller. They are a famous brew shop brewery, with years of experience, and selling their own brew packs. We shared our recipes with them and the goal is to get going before the summer of this year. The recipes have been exchanged and we expect the ball to roll soon.

As for the Netherlands, where our main production partner (Braumarkt) is based, we’ve placed a new order with 7 different brew Packs from Pale Ales; Stouts, Blonde, Saison, Weizen, and Lager that will be ready within 8 weeks.

Bart visiting current supplier, Braumarkt

Furthermore, we’re testing recipes of Brouwgebroeders and Brouwmaat. Both have made custom recipes made for MiniBrew.

Community Recipes

We are super excited that the first community recipes were sold and delivered in April.

Only one pallet for the Brave Bird is available for sale

We are looking forward to hearing what you think about the taste. Supply is limited to 150 pieces for each style, so if you haven’t yet gotten your hands on these packs, here is a link to make sure you can still try out the Brave Bird and Delfis Juice.

That bird is real and enjoying his Brewpack

Next update

In the next update, we will share more information about the progress of GEN 3, and future plans. Thanks again for your patience. Please share any feedback/thoughts in the comments. Thank you as always, and happy MiniBrewing!

Cheers

MiniBrew Team